tna SHOWCASES TOTAL SOLUTIONS AT GULFOOD MANUFACTURING 2014

events | 5 mins read

setembro 23, 2014

tna stand S1-A4, Gulfood Manufacturing 2014, Dubai, UAE, 9-11 November, 2014

Integrated packaging and processing solutions provider tna will present its range of high performance total systems at this year’s Gulfood Manufacturing. Underlining the importance of the Middle East region, tna will launch the tna intelli-weigh 0328 omega multi-head twin scale and demonstrate for the first time the benefits that food processing equipment manufacturer FOODesign’s cryo-jet® ambient & chilled air cooling systems can bring to production lines. Experts from tna’s global team will demonstrate the complete choice of solutions, including the tna intelli-flav® OMS 5 seasoning system and the tna robag® FX 3ci high speed vertical form fill and seal (VFFS) bagger.

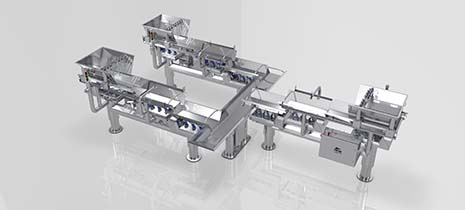

At Gulfood Manufacturing,tna will release for the first time globally its new tna intelli-weigh 0328 omega multi-head twin scale. Twin configuration packaging systems provide the lowest cost of ownership of any scale due to the reduced footprint between baggers. The new tna intelli-weigh 0328 omega twin scale takes that to a new level of performance with up to 350 bags per minute.

The tna intelli-flav® OMS 5 system delivers the ultimate in flexibility for on-machine seasoning (OMS) applications, offering consistent coverage and flavour for both wet and dry seasoning. Fully integrated with both oil spray and flavour injection systems, the tna intelli-flav® OMS 5 system provides total control of adhesion and fast flavour changes for snack lines.

Delivering unrivalled throughput of up to 250 bpm, the tna robag® FX 3ci high speed VFFS packaging machine offers production flexibility in a compact, easy-to-clean system that is suitable for a wide variety of products. Also on show is the tna roflo® HM 3 conveyor, a horizontal motion distribution system whose low force operation minimises product loss, offering speed and direction control to optimise performance. Particularly suited to heavy coated products as seasoning does not build up on the pans, the tna roflo® HM 3 has an easy-to-clean design to help manufacturers comply with strict HACCP and QA standards and reduce waste. Visitors to the stand can also see the tna roflo® VM 3 vibratory motion conveyor, which gently, yet rapidly transports more fragile products, such as snacks and confectionery, minimising the risk of product breakage and rejects.

The tna hyper-detect® 5 metal detector is the world’s first non-symmetrical balanced coil metal detector with an in-built conical aperture. Able to detect ferrous contaminants from 0.8mm to 0.9mm, non-ferrous pieces up to 1.0mm and non-magnetic stainless steel from 1.0mm to 1.2mm, the tna hyper-detect® 5 metal detector greatly reduces the risk of contaminants entering the value chain, safeguarding consumer safety and the company’s reputation.

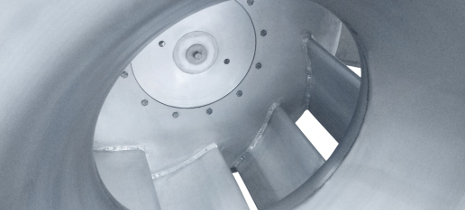

For the first time, visitors to the stand will also be able to experience FOODesign’s innovative cryo-jet® ambient & chilled air cooling systems. Cooling up to ten times faster than forced or natural convection cooling, the patented air impingement technology can be used to cool a variety of food products quickly and efficiently, while maintaining critical product properties including appearance, taste and shape.

General manager for tna Middle East, Mukul Shukla, said: “There is great growth potential in the Middle East food and packaging industry and tna has much to offer in terms of technical expertise, enabling manufacturers to boost productivity, while delivering the highest quality standards in food safety.”

For information and advice on tna’s high performance products and services, visit stand # S1-A4, Hall Sheikh Syed 1 or contact shayne.delaforce@tnasolutionscom.

ENDS

Editor’s note:

tna is a leading global supplier of integrated food packaging and processing solutions with over 7,000 systems installed across more than 120 countries. The company provides a comprehensive range of products including processing, coating, distribution, seasoning, weighing, packaging, metal detection and identification solutions. tna also offers a variety of production line controls integration and SCADA reporting options. tna’s unique combination of innovative technologies, extensive project management experience and 24/7 global support ensures customers achieve faster, more reliable and flexible food products at the lowest cost of ownership.

For over 40 years, FOODesign (a tna company) has been a leading innovator in food processing equipment and solutions for the snacks, meat and poultry, prepared foods, confectionery and bakery industries. Headquartered in Oregon, U.S., the company designs and manufactures heavy-duty, precision-built cooking and processing systems, tailored to customers’ needs. Its high performance products include cooking and baking equipment, fryers, ovens, cooling equipment, seasoning and coating machines, bulk handling conveyors, distribution and storage systems, as well as controls system technology. FOODesign also offers a range of added-value services, including project support and maintenance to ensure optimal performance and maximum return on investment.

For further information, please contact: Shayne De la Force

TNA Australia Pty Ltd., 24 Carter Street, Sydney Olympic Park NSW, 2127, Australia

Tel: +61 412 366 379 Fax: +61 297 482 970

Email: [email protected] or visit: www.tnasolutions.com

Twitter: http://twitter.com/tnasolutions

For further press information, please contact: Emma Simms / Alison Owen,

Barrett Dixon Bell Ltd., Craig Court, 25 Hale Road, Altrincham, Cheshire, WA14 2EY, UK

Tel: +44 (0)161 925 4700 Fax: +44 (0)161 925 4701

Email: [email protected] / [email protected]