Florigo launches new conti-pro pc 3 fryer with patented opti-flow technology

company news | 4 mins read

outubro 26, 2016

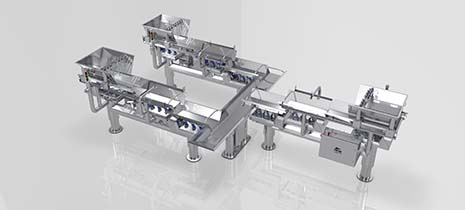

Woerden, Netherlands, 26 October 2016 – Florigo (from tna) has announced the launch of a new continuous potato chip fryer that features patented opti-flow® technology for improved frying performance. The new conti-pro® PC 3 fryer’s integrated opti-flow technology optimises the oil flow through the kettle, ensuring that each potato slice is evenly fried, limiting the formation of acrylamides and reducing the amount of rejects by up to 10 per cent.

Woerden, Netherlands, 26 October 2016 – Florigo (from tna) has announced the launch of a new continuous potato chip fryer that features patented opti-flow® technology for improved frying performance. The new conti-pro® PC 3 fryer’s integrated opti-flow technology optimises the oil flow through the kettle, ensuring that each potato slice is evenly fried, limiting the formation of acrylamides and reducing the amount of rejects by up to 10 per cent.

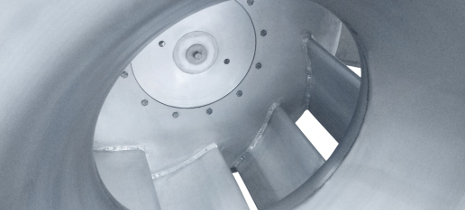

Florigo’s patented opti-flow technology is based on an innovative oil inlet section that changes the fluid dynamics within the kettle to increase oil flow speed and produce a more streamlined laminar flow over the full width and length of the fryer pan. Normally, as the oil flow increases in the fryer so does the turbulence, which can cause the oil to spin in one place, resulting in unevenly fried potato slices and therefore an increase in the level of acrylamide and rejects. Florigo’s unique opti-flow technology effectively minimises the occurrence of turbulence by removing 99 per cent of cyclone dead spots at the beginning of the fryer. This maintains a nominal flow speed throughout the fryer, preventing debris from settling and ensuring that potato slices don’t absorb or carry any excess oil. As a result, each potato chip is evenly fried, lowering the level of acrylamides and reducing the number of rejects for enhanced product quality and increased yield.

“At Florigo, we pride ourselves on providing our customers with the most innovative frying technology in the industry and our current portfolio of continuous potato chip fryers are without question the most versatile systems in the market,” comments Arnaud Jansse, applications engineer at Florigo. “However, the food industry is constantly evolving and we want to make sure that our customers have the tools they need to meet future demands in terms of yield and product quality. With our new conti-pro PC 3 continuous fryer, we were able to incorporate our unique opti-flow technology into our latest generation of fryers to ensure potato processors can stay one step ahead of the market.”

The Florigo conti-pro PC is the first fryer in the company’s portfolio of high performance processing equipment to feature built-in opti-flow technology. Other features of the Florigo conti-pro PC 3 include a product transport system with spring steel sealing, an easy-to-navigate touchscreen operating system and an insulated hood with condensation collecting pan that can be automatically lifted. The new fryer comes with a unique and durable constructed frying kettle with rounded corners and sloped bottom and is fitted with an Internal Clean in Place (CIP) system with hidden pipes in the hood to further ease cleaning and maintenance. The fryer can also be equipped with a double heat exchanger that enables the injection of cooler oil towards the end of the frying process and an integrated defatting belt to prevent potato slices from absorbing or carrying excess oil. Together with Florigo’s opti-flow technology, the combination of these three cutting-edge features helps manufacturers produce healthier products with reduced acrylamide formation.

ENDS

About Florigo Industry B.V.

With over 60 years of experience in the food processing industry, Florigo Industry (from tna) is widely known for its ability to boost capacity, improve quality and increase efficiency with its wide range of innovative food processing technology. The company specializes in the design, manufacture and servicing of high-performance processing equipment for the snacks industry, including washing, de-stoning, peeling, slicing, blanching, drying, frying, cooling and freezing equipment. Florigo’s cutting-edge patented vacuum frying and de-fatting technology helps food manufacturers around the world to develop healthier snacks with unique consumer appeal.

About tna

tna is a leading global supplier of integrated food processing and packaging solutions with over 14,000 systems installed across more than 120 countries. The company provides a comprehensive range of products including materials handling, processing, cooling and freezing, coating, distribution, seasoning, weighing, packaging, inserting and labelling, metal detection and verification solutions. tna also offers a variety of production line controls integration & SCADA reporting options, project management and training. tna’s unique combination of innovative technologies, extensive project management experience and 24/7 global support ensures customers achieve faster, more reliable and flexible food products at the lowest cost of ownership.

For further information, please contact: Wiebke Thiel

TNA Australia Pty Ltd., 24 Carter Street, Sydney Olympic Park NSW, 2127, Australia

Tel +61 412 366 379 Fax +61 297 482 970

Email [email protected] or visit www.tnasolutions.com

Twitter http://twitter.com/tnasolutions