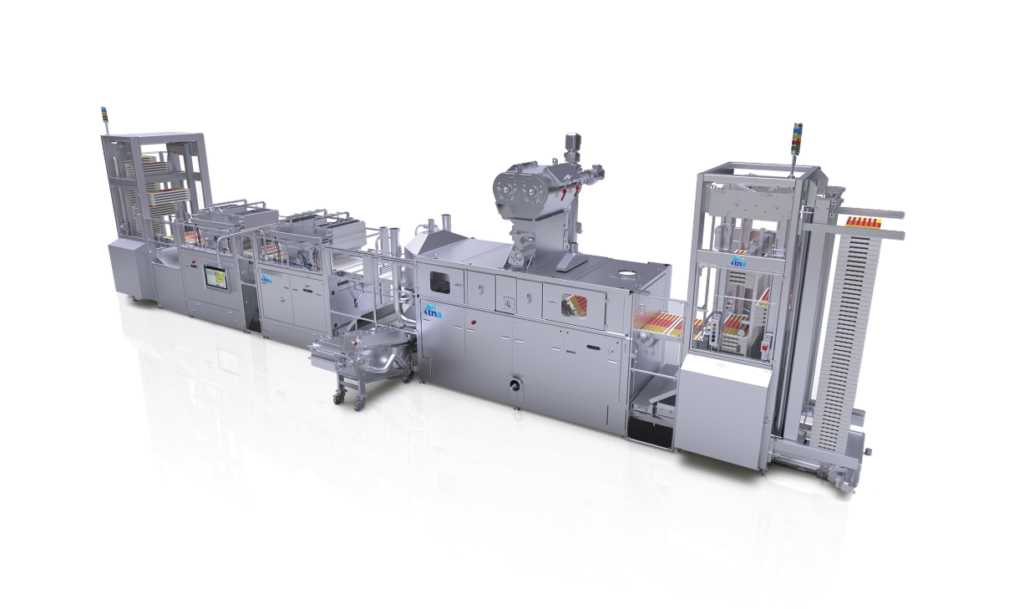

tna mogul ST

The tna mogul ST is a high-performance starch mogul designed to effectively mould a wide range of confectionery products, including gums, jellies, marshmallows, fondant cremes, centre-in-shell, nutraceuticals and liquorice. Featuring an all-in-one fully integrated feeder, starch buck, depositor, stacker and pallet transport system, the tna mogul ST offers a complete starch moulding solution. Choose from a variety of pump modules to deposit in single-colour or two-and three-colour combinations, including side-by-side, foam and starlight.

With a simple stainless-steel construction that adheres to the highest hygiene and safety standards, including ATEX, you never have to compromise product safety or factory cleanliness. In addition, the tna mogul ST enables continuous operation outside of routine maintenance, processing up to 35 trays per minute*.

*Trays per minute, subject to product type, shape and mass.

Make continuous deposits with extreme accuracy using pumps with a single, flat valve, which operate identically for all pistons / nozzles.

Ensure the highest level of product safety and factory cleanliness with hygienic stainless-steel design and controlled starch retention.

Benefit from simple operation and faster maintenance thanks to easy-access design.

Save time and maintenance costs with durable, long-lasting construction that includes simple, reliable walking beams that reduce the number of moving parts.

Source TNA parts locally from over 30 tna locations around the world to maximise uptime.

- Continuously moving tray conveyors in feeder and stacker

- Five tray sub-stack system for ultra-smooth tray-and-stack system

- Maintenance free, chainless, walking beam in the starch section

- Stainless steel contact surfaces for starch, tray and product.

- Starch sifter

- Stainless steel, hollow body depositor pumps

- Integrated electrical and control system

- PLC storage of 1000+ product recipes and parameters

- Direct connection to the TNA starch conditioning system

- Direct connection to product finishing machines

- ATEX compliance

- One, two or three depositing modules with tray-size depositing pumps in any configuration

- Extra wide maxi version suitable for longer trays delivering speeds of up to 30 TPM

- Gummies & jellies

- Confectionery processing