TNA Solutions to demonstrate how automation in the production line can ease labor shortages

March 13, 2025

Visit booth 901 at SNAXPO 2025

Coppel, TX, USA, 12 March 2025 — TNA Solutions, a global leader in food processing and packaging solutions, will present its advanced automation technologies at SNAXPO 2025 from March 30 to April 1 in Orlando, FL. As food manufacturers face increasing labor shortages, rising operational costs and evolving consumer demands, TNA will demonstrate how working with a complete solutions partner can help snack producers overcome these challenges.

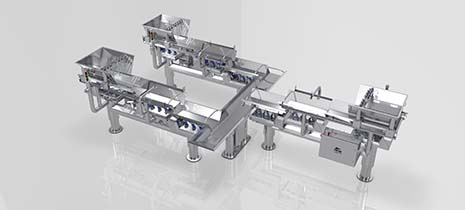

Visitors to booth 901 will see first-hand TNA’s cutting-edge equipment, including the tna intelli-flav® OMS 5.1 seasoning system and the ‘Perfect Pair’–the tna robag® 3e and tna auto-splice 3* designed to optimize production efficiency, reduce costs and deliver consistent product quality.

Tackling labor shortages with automation

The U.S. manufacturing sector is facing a critical workforce gap, with Deloitte and the Manufacturing Institute projecting that 3.8 million new workers will be needed by 2033, yet nearly half of those positions could remain unfilled. Automation is key to sustaining industry growth, enabling manufacturers to maintain production with fewer workers while improving efficiency and consistency.

Proven success: Mister Bee quadruples production with TNA Solutions

Mister Bee Potato Chips, an iconic U.S. brand, partnered with TNA to modernize its facility in West Virginia, achieving a 400% increase in production capacity. By integrating TNA’s high-speed packaging systems, Mister Bee increased production, while reducing downtime and improving efficiency with the tna robag® system and advanced auto-connect and unload assist technology.

“With TNA’s full line solution, we can now run two flavors of chips at the same time, and production has increased from 25 to 90 bags a minute,” says Mary Anne Ketelson, President – West Virginia Potato Chip Company, producer of Mister Bee potato chips.

“As labor shortages persist, food manufacturers must turn to automation to ensure operational resilience,” said Mukul Shukla, Vice President, TNA Solutions North America. “As the only single-source global partner of complete solutions, TNA offers snack producers a solution to improve efficiency, simplify operations and retain trained talent.”

The tna robag® 3e vertical form, fill and seal (VFFS) system, when paired with the tna auto-splice 3*, allows food manufacturers to run five packaging lines with just one qualified operator, achieving speeds of up to 250 bags per minute** while boosting packaging line efficiency to up to 98%. Simplified mechanical design reduces maintenance requirements, speeds up changeovers and lowers training time, making operations smoother and more cost-effective. The tna robag® 3e’s patented modular design allows fast pit-stop-style changeovers of formers and other core components.

*patent pending

**Speeds depend on tna robag® configuration, bag size, film and product type

Enhancing efficiency and product quality

Efficiency remains a top priority for food producers, particularly as 53% of U.S. consumers cite rising prices as a key concern, according to McKinsey & Company’s Consumer Wise Q3 report. Manufacturers must balance affordability with high-quality production, making automation a critical investment.

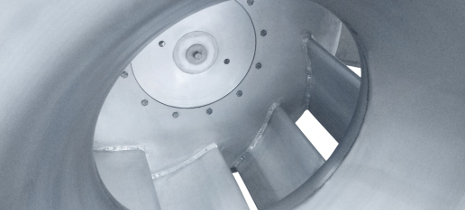

The tna intelli-flav® OMS 5.1 seasoning system delivers precise, uniform application of powder and liquid seasonings in a single drum, ensuring consistent flavor, texture and appearance. Its stainless-steel drum with an integrated heated oil system accommodates a variety of hot and cold products, including fried, baked and puffed snacks. With an ergonomically lightweight design, a rotating touchscreen accessible from both sides and tool-less changeovers, it improves uptime and reduces operator fatigue.

Meeting evolving consumer demands

Consumer preferences are shifting toward bolder, more diverse flavors alongside better-for-you snacks. Mintel reports that 37% of global snackers believe unique flavors can make healthier snacks feel indulgent, while GlobalData highlights the increasing demand for international flavors such as Korean BBQ, churro, turmeric and citrus-infused seasonings.

TNA’s intelli-flav® OMS 5.1 allows snack producers to deliver consistent, high-quality flavors across multiple product types, ensuring perfect coverage without waste. The system enables brands to innovate with new seasonings and formulations, giving them a competitive edge in an expanding snack market.

Visit TNA at SNAXPO 2025

To explore TNA’s complete solutions for snack production, visit booth 901 at SNAXPO 2025 from March 30 – April 1 in Orlando, FL. Register for the event here.

For further press information, please contact:

Nataliya Saxena

Global Communications Manager

Tel: +61 9714 2300

Email: [email protected]