Designed for fresh produce: tna roflo® VM 3 High Throw Vibratory conveyor

products | 2 mins read

February 24, 2014

Vibratory conveyors are effective for transporting a wide range of products; however, handling loose-leaf salads and delicate fresh produce presents its own challenges, such as clumping and uneven flow which can impact line efficiency.

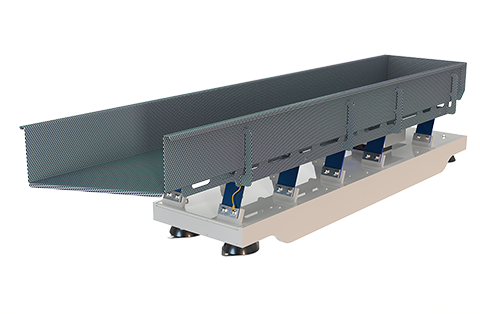

To address these challenges, TNA’s development team designed the tna roflo® VM 3 High Throw vibratory conveyor, specifically engineered to minimise clumping and sticking when conveying produce. The system features an innovative ‘high throw’ action and a dimpled pan design that minimises surface contact which makes it particularly suitable for handling lettuce, spinach, and other leafy greens.

A key innovation of the tna roflo® VM 3 High Throw is its ‘H’ base design. Traditional conveyors often use square hangers to attach the springs responsible for vibratory motion; however, increased movement can cause these hangers to experience excessive stress, leading to frequent breakdowns. The ‘H’ base’s curved shape distributes torsional stress evenly, enhancing durability and ensuring effective vertical lift of the product. This design smooths out lumps in the product feed, maintaining consistent flow and reducing downtime associated with maintenance.

Beyond the tna roflo® VM 3 High Throw vibratory conveyor, TNA Solutions offers a comprehensive range of horizontal motion and vibratory motion distribution systems.

The tna roflo® distribution systems are used by the world’s best-known brands and can be integrated together to handle a wide range of applications and product types including – fragile and coated product, sticky confectionery, potato products, and snacks.

TNA specialises in creating bespoke solutions tailored to specific production requirements, providing customised solutions to suit any application type.